This is the ultimate content hub for new and amateur golfers looking to play better and lower their score. Below are a bunch of resources on how to golf today.

I’ll walk you everything you need to know, from:

- Buying your first set of golf clubs

- Picking the right golf ball

- Golf tips that all of the pros are using

- How to lower your score on the course

This content hub is regularly being added with new tips, tricks, and information on how to play golf no matter where you live.

Golf Equipment

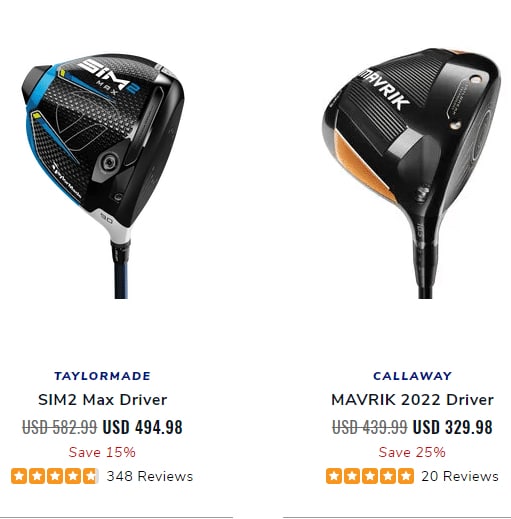

The first thing you need to do if you want to play golf is buy a set of golf clubs to use out on the course. You can do this two different ways: buy a complete set of clubs or buy individual clubs until you have the set you want.

A full set of golf clubs will come with at least one driver, iron, wedge, and putter. Most sets today include up to 14 different clubs (the maximum a golfer can carry) and come with a golf bag to.

If you want to do a bit more research and buy your own clubs, here are some key guides to look through:

If you are really new to golf, then you might want to stick to beginner clubs. Beginner golf clubs sacrifice control in the name of helping you get good launch up off of the ground.

Here are some beginner golf club guides:

For the most part, all of the best drivers come with a beginners version with more forgiveness and a higher loft.

Golf Accessories

After you have a set of golf clubs, there are a few key accessories you need before you go go golfing. Use the guides below to browse and find everything you need:

Golf balls, tees, and a bag are mandatory before you can go out to the course.

As you get more serious golfing, there are a few optional golf accessories that most players like to have:

How to Play Golf: Fundamentals

Before you start playing, there are a few basic golf rules, tips, and fundamentals that you should know.

The Goal of Golf

The basic goal of playing golf is to get the ball into the hole in the least number of strokes you can. Your goal is to have the lowest score you can after 18 holes.

This is done by hitting your ball off the tee box (first shot), fairway (short grass), rough (longer grass), and green (shortest grass).

Once you are ready to play golf, there are a few common ways you can learn how:

- Book an in person lesson at a golf course

- Go out to the driving range and practice for yourself

- Sign up for online golf lessons and practice at home

If you decide to practice at home, you’ll want to buy a hitting mat and a practice net so that you can hit really hit balls.

Golf Scoring

Knowing how to keep score is a key golf fundamental. Each hole has a posted score which is known as the par score. This is the number of strokes that a scratch golfer (a zero handicap player) should take in order to complete the hole.

If you finish a hole in less or more than the posted number of strokes, there are terms for that:

- Three under par = Albatross

- Two under par = Eagle

- One under par = Birdie

- One over par = Bogey

- Two over par = Double Bogey

- Three over par = Triple Bogey

- Four over par = Quaduple Bogey

Swing Basics

To help you get started, we have a bunch of free guides that go over some basic golf shots and techniques.

Check those out to help you get a head start

The above golf fundamentals are guides that we’ve put together here at Hitting the Golf Ball. We are constantly adding more content as we see fit.

Are you’ve played a few rounds, come back here and follow our guides.

Make sure you have a good understanding of the golf rules before you head out to the course. The full list of United States Golf Association (USGA) rules are here and they go over a number of key points:

- How to properly fill out a golf scorecard

- When to take a one-stroke penalty

- Basic golf etiquette rules

- Different forms of play

- Modified rules for amateur golfers

The Short Game

A lot of golf strokes can be saved or added in the short game. The approach shot is your second or third shot when your objective is to get the ball onto the green and set yourself up for an easy putt.

Here are some tips and tricks on how to hit good balls from a shorter distance:

The approach is one of the best golf shots you need to learn.

Putting

The putter is unlike any other club in your golf bag. With other clubs, you need to work on getting as much power in your swing as possible. With a putter, the goal is to create a consistent pendulum motion and correctly judge your speed in order to get the ball in the hold.

There are two types of putter styles you can buy: blade or mallet. Each style has a few pros and cons and the ultimate choice is yours. The guide below explains the key differences and considerations between each.

Here are some of the top putting tips you should follow if you want to learn how to play golf correctly:

If you putt the ball twice on every hole, 36 strokes per round will be with your putter. Learning how to control the ball properly is key towards breaking 100 and lowering your golf handicap.

Golf At Home

If you want to get really good at golf, you need to hit balls as often as you can. A popular trend (especially since the pandemic) is to buy home golf simulator equipment so that you can play real golf right from within your golf.

A golf simulator is a package of equipment that includes a launch monitor, which helps to calculate your swing speed, angle, and ball movement each time you swing the club. The launch monitor is packaged up with a hitting mat, net, and simulator software.

Golf simulator software allows you to play real life courses, where your ball is simulated on the screen each time you hit it.

Here are the best golf simulator packages to check out today:

If you want to do a little bit more research instead of buying a full kit, we have guides on some of the best at-home golf equipment you can buy today:

Golf Tips

Golf is an easy sport to learn, but very hard to master. Hopefully the links within this content hub help you learn how to play golf better.

Here is a selection of other golf tips to help you get started:

- How to Clean Golf Clubs

- How to Calculate Golf Handicap

- Average Golf Club Distances

- How to Lower Your Golf Score (Get Better)

- Online Golf Lessons

Watching Golf

One of the best ways to learn the golf game and pick up nuances in the game is to watch it on TV. The Professional Golf Association tour (PGA tour) is the main men’s league in North America. Weekly professional tournaments are broadcasted on TV for you to follow along. The equivalent female tour is the Ladies Professional Golf Association, or the LPGA.

There are equivalent tours in Europe and Canada as well, along with the Web.com tier-2 league as well.

And that is everything you need to know if you want to learn how to play golf! All of the links and guides on this page will make you a better golfer today.